If you want to use your tattoo machine for many years, then, maintenance should always be your priority. It’s usually subjected to a lot of vibrations, which makes it easier for some components to either fall off or break. In addition, some parts could be loose, hence, affecting the accuracy of your job, not to mention the danger of injuring your client due to an uncontrollable machine.

Remember, the amount of strains and pressure resulting from the daily activities makes the equipment susceptible to wear and tear. Of course, a tattoo studio might have many tattoo machines, but what if your favorite one breaks down? Therefore, to avoid inconveniences, especially in the middle of a tattoo job, it’s essential to ensure that the machine is regularly maintained. Read on to find out more tips on this subject.

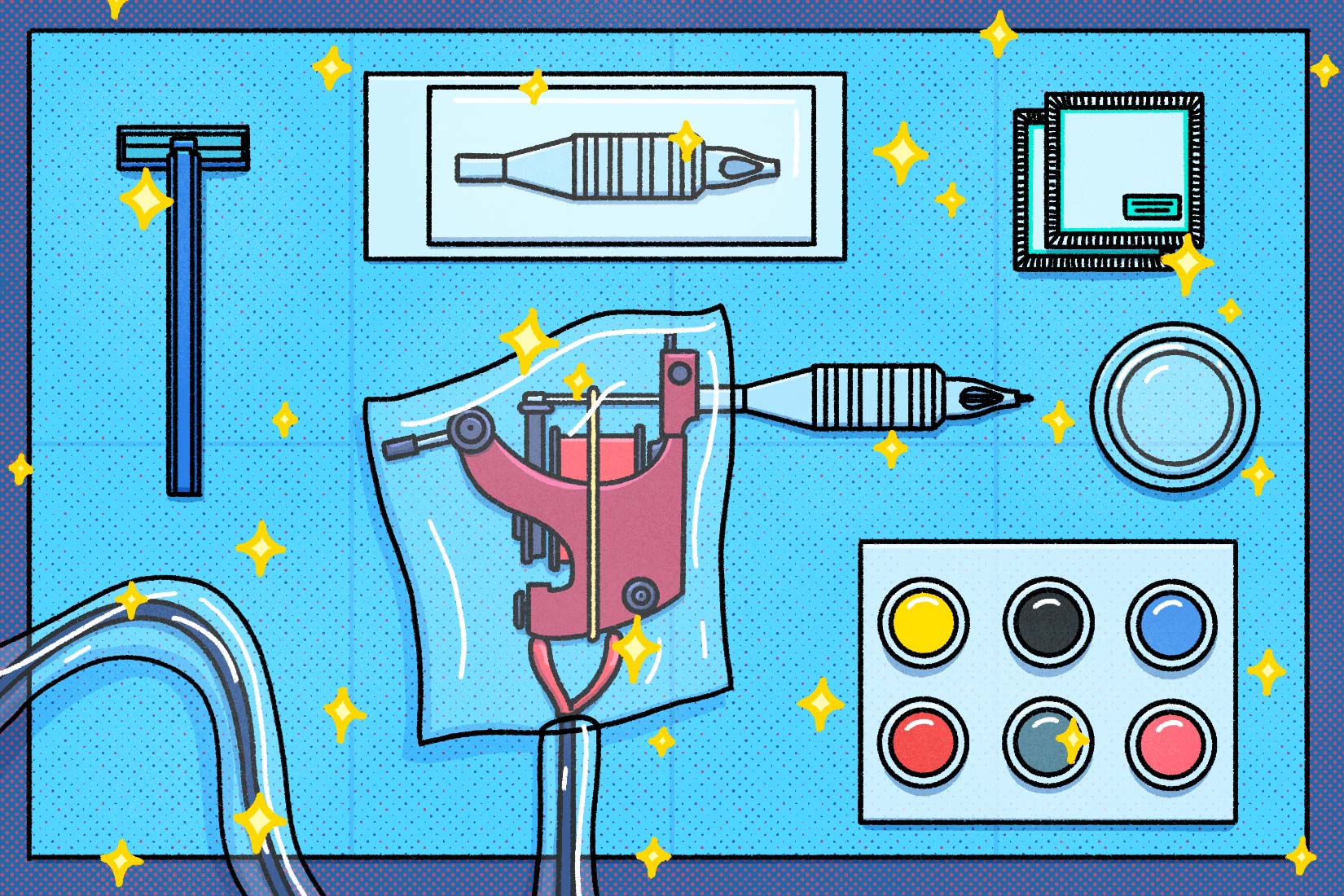

Invest In Cleaning Equipment

The first rule for any tattoo artist is to ensure that the machine is clean before working. The potential health risks associated with reckless tattooing can never be ignored. Apart from the physical pain caused to the client, your business will also come under scrutiny, and you might lose everything if sued. So, before you begin any task, always make sure that the machine is as clean as new.

See Also :- Striking Henna Tattoos Design for Girls

There’s no one way of carrying out this maintenance procedure, but it would help if you invest in high-quality cleaning tools, such as:

- Clinical disinfectant: This is one thing that must be on the list. If used correctly, it will leave no room for microorganisms and other disease agents to survive.

- Ultrasonic cleaners: These items will also be of significant use, especially when dislodging ink residue on tubes before manually cleaning them.

- Autoclaves: Finally, you can buy autoclaves to provide the much-needed assurance that all parts of the machine are sterilized. They create a pressurized environment that, in turn, kills all the viruses and bacteria.

How Should You Keep Your Tattoo Machine Clean?

Having all the tools mentioned above will only be a good investment if you use them correctly. So, how will you use them to keep your tattoo equipment clean and safe? But, before delving deep into the cleaning process, it’s worth noting that there’s been a lot of debates on whether or not you should cover the machine while in use.

Well, many experts recommend bagging your equipment; but, it’s all about what works best for you. This will help keep your machine very clean even if you accidentally touch it with dirty gloves. In addition, it prevents contamination from ink splats or other splashes that might occur while working on your tattoo design. It may get slightly hot when bagged, but that shouldn’t be much of a problem. Once you’re done tattooing, remove the bag and proceed to the cleaning phase.

Never use the following techniques as these will only damage your machine:

- Don’t use running tap water as it may lead to short circuiting

- Don’t opt for bleach as your cleaning agent. It will corrode the springs and also create a favorable environment for rust.

- Don’t disassemble the machine when cleaning. Drops of ink or water might make their way to some critical parts and cause the machine to malfunction.

On the other hand, here are some of the steps to clean your machine effectively:

- First, find the best disinfectant from the store and spray it on the machine. Wait for about ten minutes, then, wipe off all the deposits. It’s important that you do so because these particles might lead to rusting.

- Now, spray the machine with rubbing alcohol, then, get rid of any remaining deposits left by the disinfectant. The final and very important step is the lubrication process—more on this below.

Regular Lubrication

Of course, during the cleaning process, you’ll be gradually eroding the upper surface of the machine. The finish that appears on top of your equipment might not seem important, but it’s very critical that you maintain it. Peeling it off and exposing that area will eventually attract rusting. Whether you’re just starting a tattoo bus or already have an established venture, you’d want to prevent such things from pulling down your revenue.

However, this should not stop you from cleaning your machine thoroughly. The solution is to lubricate the affected areas periodically using the right lubricant. If you’re not sure which product to use, then, you can go with olive oil as it seems to work for most of these situations. The main reason why experts recommend this oil is due to the fact that it’s not toxic to humans. Therefore, if it accidentally comes into contact with the wound or the client’s skin, it won’t do any harm.

But, there’s a wide array of options when it comes to lubricants. WD-40, silicone, or related products will also do fine when used to cover the exposed areas of the metal. The thing with these lubricants, however, is that you’ll need to be extra careful when using them. Although most of them are harmless, some might have a few side effects when they come in contact with one’s skin.

So, how do you lubricate your machine the proper way? Apply a little amount of oil over the surface using a paper towel. Make sure you reach all the necessary parts. If an area is too remote, you can use a cotton bud. Don’t forget to oil the springs and armature bar as these parts are susceptible to rusting, too. If your machine is finished with powder-coated paints, lubrication might not be necessary. Read the manufacturer’s manual if in doubt.

Conclusion

As an artist, the tattoo machine is the most crucial part of your business. In other words, without a properly functioning tool, you’ll be quite limited. As such, it’s important that you prioritize the safety and cleanness of your equipment. One way of doing so is by investing in high-quality cleaning tools, and making sure to use them correctly.

To avoid any rusting after the cleaning process, you’ll need to lubricate the surface. It’s up to you to find the lubricant that works best for your needs. Olive oil, however, remains to be the best choice because of its human-friendly nature. Remember that this technique is not necessary for those machines with powder-coated paining.